BLOG

REV: A Walk-Through New Automation for Smartphone Grading

May 10, 2021

A series from our whitepaper, ‘The Secondary Smartphone Market REVolution’

As we have established, REV machines will improve the process of repairing and refurbishing mobile devices through automation. They will perform continuous processing by holding phones in place and bringing the tests to the devices for a significantly faster and more accurate operation.

Let’s explore the six steps that make this work.

Of course, there is more to the REV solution than its robotic arms and pallets. The other side of REV is the software engine that controls the hardware.

This engine will run scripts to ensure that customer requirements are followed. It will offer real-time dashboards that display individual device statuses. It will also keep a record of all testing data so that customers can make better decisions about what to do with their devices. The data can be used to advise on how to repair or upgrade a device.

The productivity gains from REV are remarkable:

If you are working in the secondary handset or mobile diagnostics, we’d love to hear from you! To find out more about REV, please visit www.ingrammicroservices.com/REV

As we have established, REV machines will improve the process of repairing and refurbishing mobile devices through automation. They will perform continuous processing by holding phones in place and bringing the tests to the devices for a significantly faster and more accurate operation.

Let’s explore the six steps that make this work.

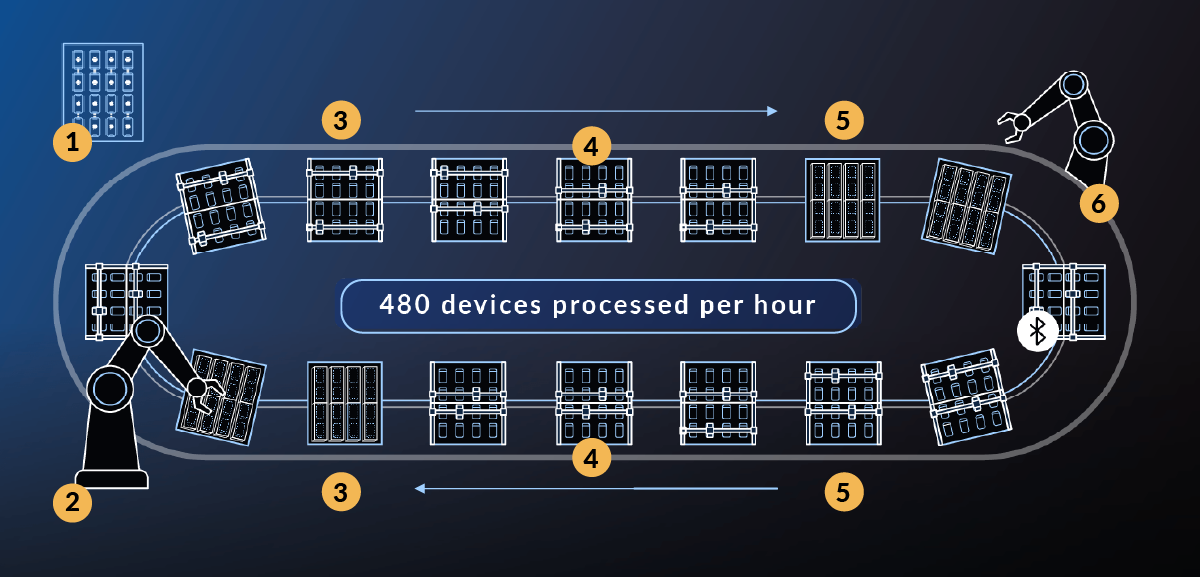

- Operators plug in the devices. At this stage, the devices are also loaded with software and a QR code, which allows the REV system to complete various functional tests.

- Robotic arms place phones on 16 pallets, which can each support 16 phones. The pallets keep the devices plugged in across the entire process. This means the phones are always being powered so there is no need for pre-charging.

- The pallets move around a 20 ft x 4 ft oval ‘racetrack’ circuit. It takes half a circuit to complete a test, so REV can process two batches simultaneously.

- At various stages of the circuit robotic arms perform multiple functional tests on the devices. Customers can specify which tests are needed.

- The final test is for cosmetic grading. This is the point at which REV takes a hi-res photo and uses photometric scanning to identify blemishes.

- The devices complete their journey around the oval circuit. Robotic arms remove them at unload stations. Devices are then divided into two categories: ‘suitable for improvement’ (i.e grade skipping) or ‘put away’.

Of course, there is more to the REV solution than its robotic arms and pallets. The other side of REV is the software engine that controls the hardware.

This engine will run scripts to ensure that customer requirements are followed. It will offer real-time dashboards that display individual device statuses. It will also keep a record of all testing data so that customers can make better decisions about what to do with their devices. The data can be used to advise on how to repair or upgrade a device.

REV by the numbers

The productivity gains from REV are remarkable:

- A single REV machine will process around 480 devices per hour — that’s nearly 1M devices a year!

- In addition to improving output, REV will reduce labor costs associated with device processing.

- Just four people are needed to run the process, compared to the 250 people it takes to achieve a similar outcome through manual processes.

- REV represents a 10x improvement on the current industry standard for processing times. Today, average grading and testing costs run as high as $20 per device and REV can halve that outlay.

Is REV for you?

If you are working in the secondary handset or mobile diagnostics, we’d love to hear from you! To find out more about REV, please visit www.ingrammicroservices.com/REV

Categories